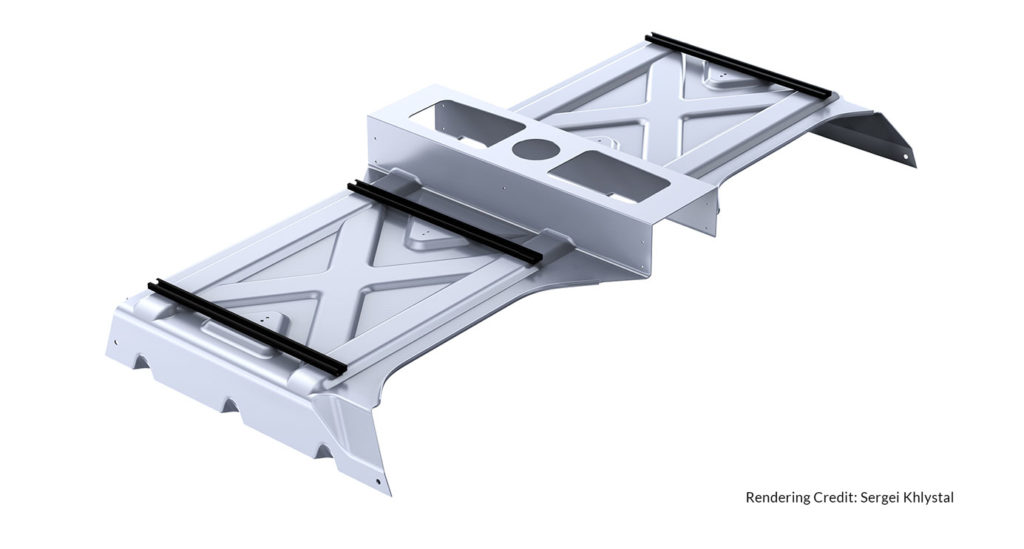

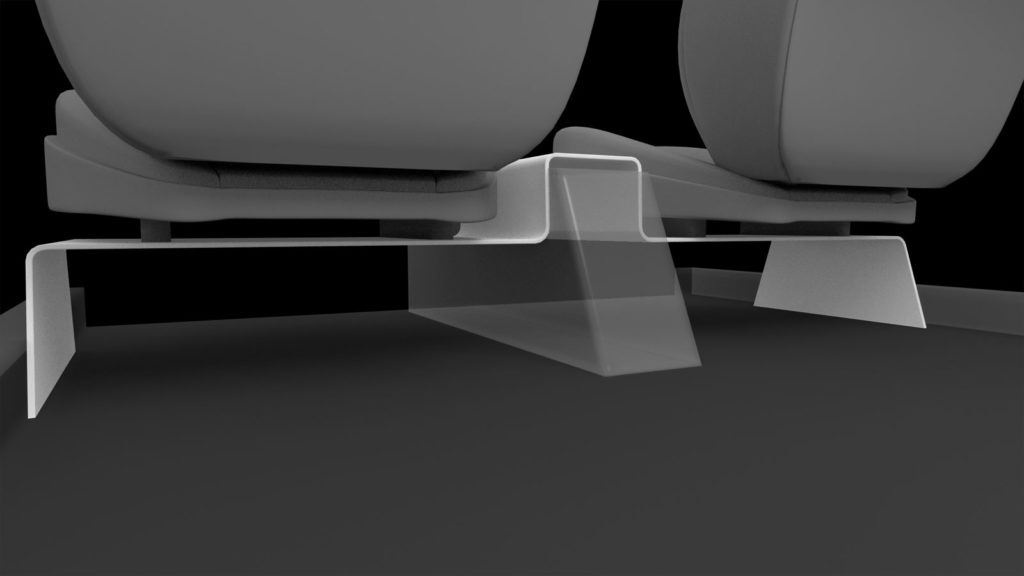

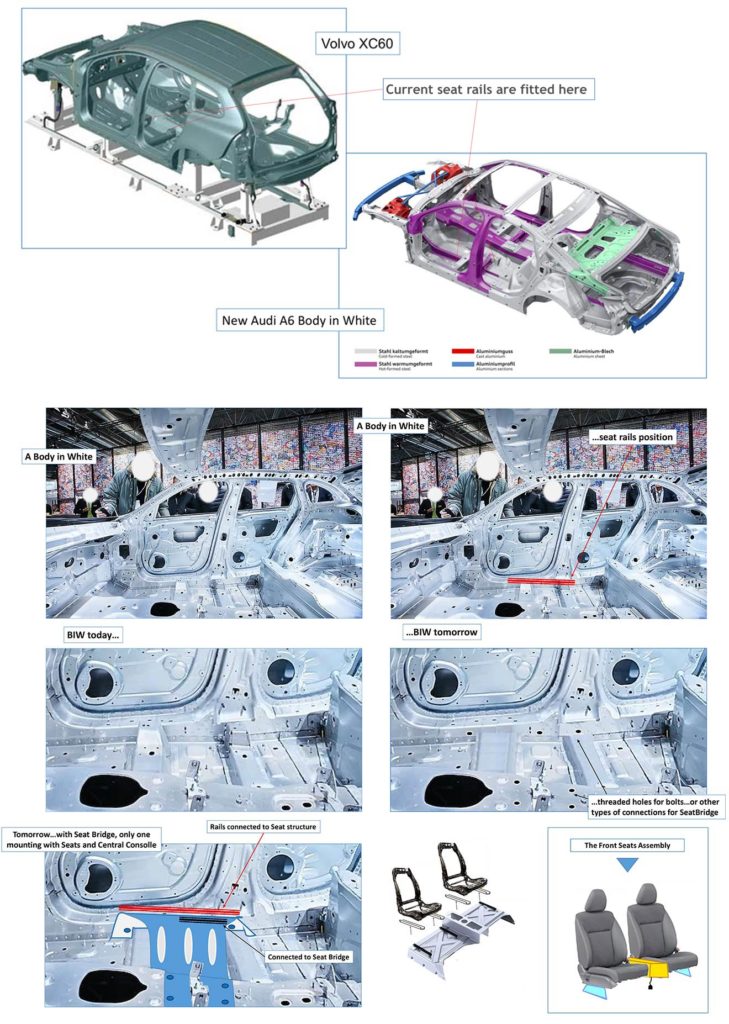

- The bridge connects two door lower members with support from center tunnel.

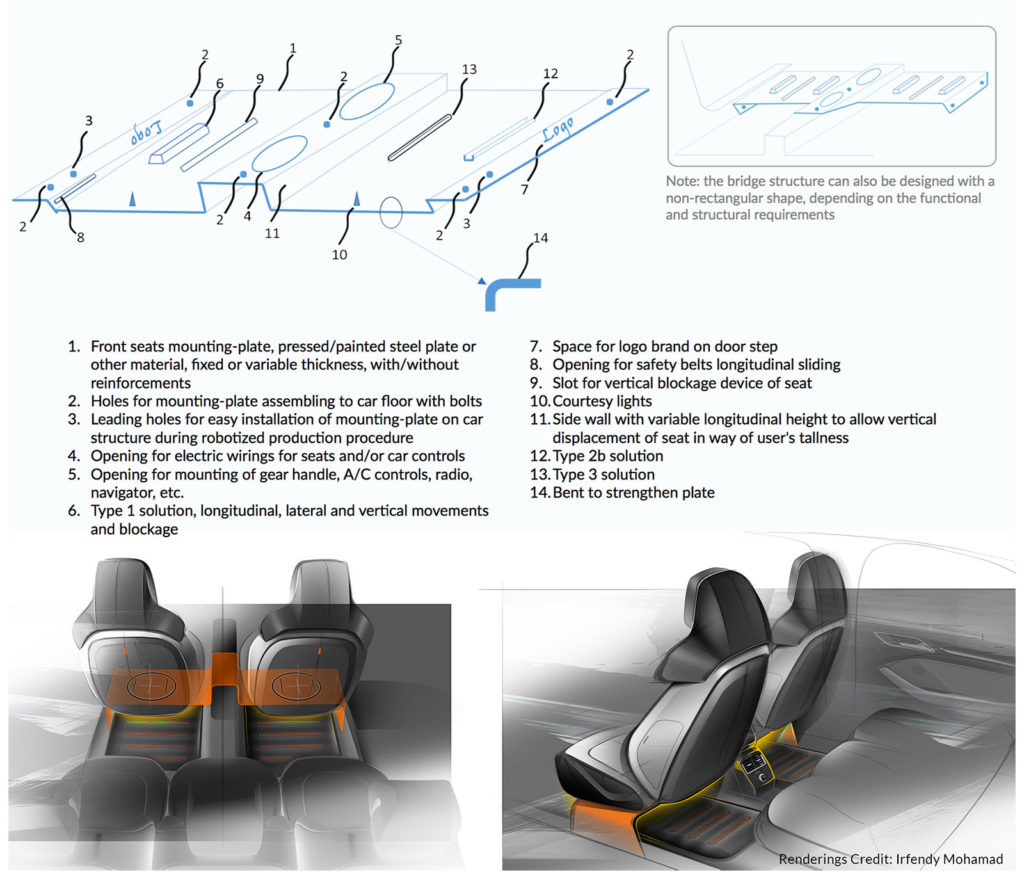

- Seat layout with short slide travel could benefit from this solution

Mounting a seat structure on a podium or seat bridge structure is something car makers take benefit of to bridge the gap between the carryover seat structure and carryover floor on the existing BIW. However, it is certainly not spacious laterally and aesthetically pleasing for rear seat occupants.

Seat Bridge Structure by SINTEC

Current Scenario

At present, Driver and Passenger independent seats are mounted separately and directly on floor cross members. These rails provide an easy way for adjusting the seat longitudinal position, but have a major drawback: they significantly reduce the lateral foot space available to the rear passengers, also reducing the comfort and without any aesthetic and potential injury to feet.

Seat Bridge Solution

A Seat Bridge is connected to the car structure in door sill and centre tunnel areas. On this bridge, Seat Structure mounting and Center console mounting is available. This Approach improves the accuracy of Seat slide mounting on the floor and Centre console position.

Seat Bridge was granted Italian Patent N. 102016000060616 and is expected to complete the European patenting process for the following concept

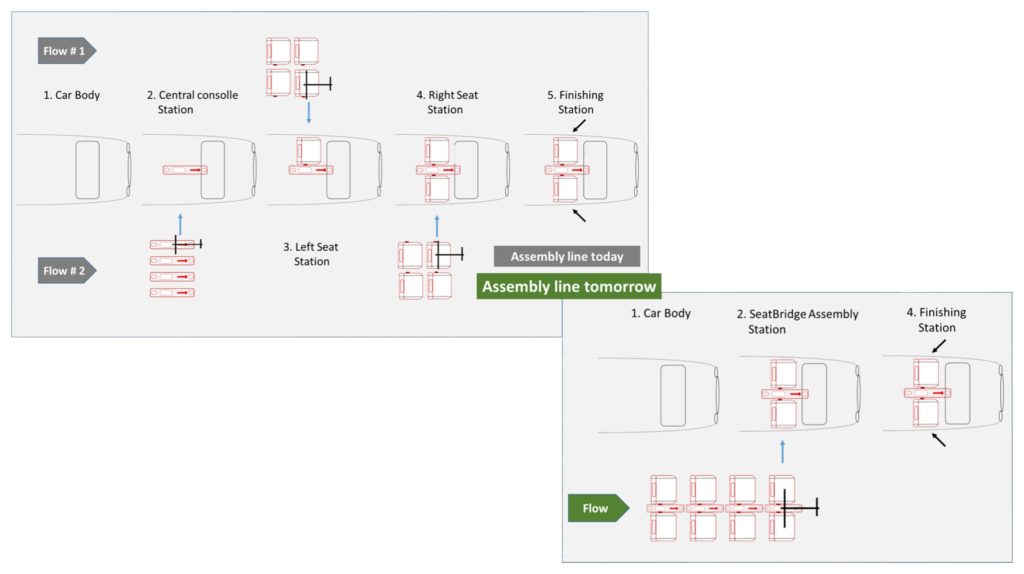

Production Line Improvement

Instead of 3 independent units RH and LH seat assemblies and Center console, the bridge unites all at one platform and is assembled on BIW. At the vehicle JIT line, mounting control is required only for Bridge. on the JIT line, it shall take away all hassles of seat position control and alignment and clearance and gap management. This is could be a good solution for quality management and improvement.

With a single bridge and with the potential feasibility of mountings for multiple modular seat frames, many seat grade options could be possible and Carmakers will have the flexibility to choose multiple seating suppliers for a project if necessary. The major benefit of EV car floor layouts is the ability to achieve a flat floor.

However, with reduced space between bridge and cushion, the Seat frame structure packaging needs reconsideration. The concept represents minimum block height but an adaptation of the existing seat structure ( 2wp~30way power seat ) will be challenging. As the Center portion is hanging, Bridge needs high strength to meet the Belt anchorage strength and limit occupant displacement during crash. With a longer slide rail travel, The bridge overall length will increase thereby increasing weight and cost to meet performance and strength.

Assembly process in JIT, wire harness layout and Servicing would add to challenges however on a new platform with more consideration, this solution could find a potential implementation

More about SINTEC

SINTEC was founded by Claudio Buccini, a naval and mechanical graduated engineer who served the Italian Navy and worked – amongst the others – at Riva Shipyard, Wally Group and Finmeccanica Spa, always at the executive level.

More info on website: https://www.seatbridge.com/

Images Source and Credit: SINTEC